|

|

|

|

|

| |

Coil Straightener |

| Quality product for coil feeding in Press Feeding Lines |

|

|

|

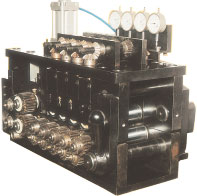

| Coil Openable Straightener head 9 x 50 Dia. |

Precision Straightener 9 × 50 Dia 150mm (w) |

|

|

| Straightener 9 x 50 mm Dia. 150mm (w) |

Straightener 7 x 65 DiA 400mm(w) |

| |

|

|

|

| |

|

| |

FEATURES

* The units are fabricated from steel and the straightener rolls are properly fixed and aligned in machine and ground housing.

* One/Two sets of drive pinch rolls are provided as required.

* All the feed Rolls & Bottom Rolls are driven, while Top Rolls have individual adjustments.

* All the Rolls are made of Special Alloy Steel Material Hardened, Ground, Chrome plated & are housed into precision needle bearing sealed at both ends.

* Upper straightening rolls are independently adjustable and once set, gang adjustment can be done for repeat operations.

* Gang adjustment of top roller blank for straightener with more number of rolls & for straightener of lesser thickness range.

* Roll setting scale on side plates/Dial gauges in some models.

* Entry Guides.

* Exit cascade rolls.

* Control Panel with Suitable loop control system to maintainloop of coil for the machine via Antenna Type loop Controls / limit arm through limit Switches.

* Fixed line speed / Variable line speed above 15 Mtr. / min.

OPTIONS

* A.C. variable driven coil straightener are available on request.

* Ultrasonic / photoelectric loop controls.

* Remote pendant control (jog forward / reverse)

* Decoiler - Straightener mounting on common base.

* Inclined head mounting.

* Centralized lubrication system.

* For heavier thickness range,pinch rolls are operated pneumatically / hydraulically.

* Openable top straightener head blank mechanically or with

Pneumatic / Hydraulic Cylinder. |

|

|

|

|

|

| |

|